![]()

Contents: Ford F-series, and other aluminum-bodied vehicles; Basics; Esoteric Flaws; Short, Stubby Antennas; A Few Notes On Motors; Standard Sized Antennas; Spirally Wound Antennas; Automatic Band-Switching Antennas; Monoband Antennas; Notes On Whips; Odds & Ends;

Ford F-series, and other aluminum-bodied vehicles

Ford's F-series, aluminum-bodied pickup trucks require special installation practices with respect to galvanic corrosion. Here is the bulletin from Ford which explains what must be done to prevent galvanic corrosion. The results of failing to follow Ford's guide lines are predictable, and not covered under warranty! If in doubt, contact your local Ford dealer for details. Further, antenna mounting hardware should be aluminum, not steel, and properly mounted as recommended by Ford. And bonding is not required, as Ford has done that for you!

The same basic rules apply when mounting antennas on any aluminum bodied vehicle. However, their manufacturer's recommendations may be different than those outlined in the above bulletin. When in doubt, contact your dealer's service staff and/or the manufacturer's customer service staff.

It should be noted that most antenna manufacturers use steel in their mounting brackets and/or attachment fittings. In some cases, this eliminates using that brand and/or model of antennas. Or at a minimum, a major change in the mounting hardware and/or location.

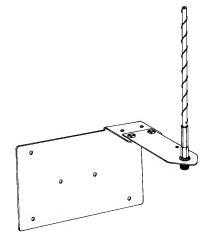

Mobile antennas appear to be a very simple chunk of hardware, when in fact they are a very complex resonant circuit. They come in every imaginable configuration (see right photo), and almost all of them will allow you to make contacts, even DX ones, if there is sufficient SNR on both ends of the contact. However, their efficiency, overall length, quality, design, sturdiness, ease of mounting, and selling price all vary. Choosing any one or more of these specific attributes, is no guarantee you're getting another one included! The most important attribute is overall Antenna Efficiency, and that's well covered in the highlighted article. So what we're going to cover here are a few pitfalls to avoid. One of those is SWR.

Mobile antennas appear to be a very simple chunk of hardware, when in fact they are a very complex resonant circuit. They come in every imaginable configuration (see right photo), and almost all of them will allow you to make contacts, even DX ones, if there is sufficient SNR on both ends of the contact. However, their efficiency, overall length, quality, design, sturdiness, ease of mounting, and selling price all vary. Choosing any one or more of these specific attributes, is no guarantee you're getting another one included! The most important attribute is overall Antenna Efficiency, and that's well covered in the highlighted article. So what we're going to cover here are a few pitfalls to avoid. One of those is SWR.

All decent HF mobile antennas require some sort of impedance matching to obtain a responsibly SWR. When they don't, it just means the resistive losses are high—read that as low in efficiency. Overall length is also important in obtaining good efficiency. The reason is, radiation resistance (Rr) is a square function of (electrical) length, and how the RF current flows over that length. What this says is, a 9 foot long antenna, will have twice the Rr of a 6 foot antenna, and twice the efficiency, all else being equal. These lengths are approximately those of a short stubby antenna, and an average length one.

Further, you don't want to get suckered into believing that large diameter coils (>3.5 inches) are better than smaller ones, because they're not! And stay away from antennas which have large metal end caps and/or plungers, as they have sub-par efficiency levels. Adding insult are non-permanent mounting (lip, clip, and magnet mounts), as they add to the abundance of ground losses, which are already too high in every HF mobile installation!

Reiterating a two important points: Loading coils are considered a lumped constant. They are there to cancel the capacitive reactance all short vertical exhibit. The do not add to the electrical length of the antenna, and they do not radiate contrary to anecdotal belief.

Last, but not the least, important point: The use of an antenna tuner, built in or external, to match an HF mobile antenna, does nothing more than add loss to an already lossy antenna installation. It does not make the antenna resonant. It does not reduce line losses. It does not reduce the SWR at the antenna. It doesn't make the antenna more efficient. And, the ability to work any station, DX or otherwise, does not negate these premises.

Screwdriver antennas dominate the remote controlled market, and for good reason. There is a lot to be said about changing frequency while under way. However, besides the aforementioned end cap problem, there are lesser known ones which needs to be mentioned.

At least one model has a weather-sealed coil assembly. In some weather conditions, water condenses in the inside of the coil, and mast. It collects in the mast, and eventually reaches the motor assembly. The results are obvious. The manufacturer denies the problem exists, and blames the issue on power washing.

Some models have relatively short masts (≈2 feet). In some installations this places the coil very close to body sheet metal. There are accessory masts available which raises the coil 1 to 2 feet. Even without a lower mast extension, some screwdriver designs place the motor as much as 20 inches above the base of the antenna. Either mounting scheme drastically raises the RF level imposed on the motor leads. It is best to avoid antennas designed this way.

The resonant frequency of a screwdriver antenna is adjusted by changing the length of the coil above a contact assembly, mounted at the top end of the mast. The unused portion of the coil, stored inside the mast, is typically not grounded except in rare cases. Regardless of the design, the unused portion of the coil still has a fair amount of circulating currents flowing through it, and excessive circulating currents can destroy the coil. Thus replacing a 6 foot whip with a 3 foot one to enable operation on 10 and 6 meters, can cause the coil to self destruct. The best advice in these cases, is to use a separate antenna to cover these bands. This fact points to another issue.

Contrary to popular belief, it is almost impossible to design a remotely-tuned mobile antenna to cover 80 through 6 meters, much less adding 160 meters to the mix.

Too many antenna manufacturers overrate the power handling capabilities of their various models, but that's not the whole story. Part of the efficiency equation is the magnitude of ground losses, which is power absorbed heating the air, and not being fed to the antenna! For example, the Comet UHF-6 (shown right) is rated at 120 watt SSB (PEP). Its manual clearly states The UHV-6 was designed to be lip mounted using the CP-5M or HD-5M. If you were to correctly mount one by drilling a hole, a 100 watt transceiver can easily destroy the antenna!

Too many antenna manufacturers overrate the power handling capabilities of their various models, but that's not the whole story. Part of the efficiency equation is the magnitude of ground losses, which is power absorbed heating the air, and not being fed to the antenna! For example, the Comet UHF-6 (shown right) is rated at 120 watt SSB (PEP). Its manual clearly states The UHV-6 was designed to be lip mounted using the CP-5M or HD-5M. If you were to correctly mount one by drilling a hole, a 100 watt transceiver can easily destroy the antenna!

There are several screwdriver antennas rated at 200 watts PEP. Although they get warm during normal operation due to the rather high resistive coil losses (low Q), typically there's no permanent damage done. However, driving one with much more than 25 watts during tuning can damage the coil assembly beyond repair! As above, the scenario is exacerbated by proper mounting (reduction of ground losses).

Lastly, several screwdriver antenna designs incorporate a slip clutch or gap in the all-thread drive screw assembly to avoid motor damage once the coil reaches its end of travel (up or down). This negates the use of any automatic antenna controller, whether it be a turns counter unit, or one which measures end-of-travel stall current. In other words, only manual control is possible, and that is a major drawback in a mobile scenario.

![]() Short, stubby, remotely controlled, HF mobile antennas (like the Yaesu ATAS-120 shown at right) seemingly have become all the rage. They're popularity is in part due to their diminutive size (less than 7 feet overall), light weight, apparent ease of mounting, and presumably their spousal approval rating. They're not necessarily less expensive than their stable mates, nor are they anywhere near as efficient. In fact, the Yaesu ATAS antenna is the least efficient, remotely controllable, HF mobile antenna, money can buy! The list price is 0ver $460, with the street price hovering around $375, not including the mount. It uses an SO239 type mount which is one of its major drawbacks.

Short, stubby, remotely controlled, HF mobile antennas (like the Yaesu ATAS-120 shown at right) seemingly have become all the rage. They're popularity is in part due to their diminutive size (less than 7 feet overall), light weight, apparent ease of mounting, and presumably their spousal approval rating. They're not necessarily less expensive than their stable mates, nor are they anywhere near as efficient. In fact, the Yaesu ATAS antenna is the least efficient, remotely controllable, HF mobile antenna, money can buy! The list price is 0ver $460, with the street price hovering around $375, not including the mount. It uses an SO239 type mount which is one of its major drawbacks.

Its mechanical and electrical aspects are also questionable, as is its operating methodology. The driving transceiver sends a DC voltage (<8.3 or >9.7) causing the antenna to move to a lower or higher frequency respectively. The SWR detection has two levels; over 2:1, and under 2:1. There is no choke in the control lead (coax) which makes common mode current a given problem exacerbated by the type of mounting usually employed. This fact is even alluded to (Installation Point 2) in the Owner's Manual! By the way, if excessive common mode is present (caused primarily by poor mounting techniques), it is possible to destroy the internal control circuit board. The board is not available as a replacement part!

Owners of short, stubby antennas typically resort to trunk lip mounts (K400, click on left photo to enlarge), luggage rack clamp mounts, and even mag mounts. All of these add to the overall losses, including the mini-sized coax most of these mounts utilize. These losses are seldom noticed because owners have nothing to compare them to. If they can make contacts, especially DX ones, that's all they seem to care about.

No matter the brand, all short, stubby antennas have an excessive level of RF flowing on their control leads, and coax cables too (common mode currents). Thus choking off common mode current is especially important if you're using (or plan to use) an automatic controller. The requisite chokes need to be mounted outside the vehicle, and as close to the base of the antenna as possible. This requirement is very difficult to accomplish when using a clip mount; a fact which should be considered before purchase.

None of the current batch of short, stubby antennas requires any impedance matching because their inherent resistive losses bring their input impedance close to 50 ohms. This means, the antennas are not DC grounded, and therefore tend to be noisier than their big brother counterparts, especially in rain and/or dusty conditions.

If you're intent on using one, keep the aforementioned inherent problems (and shortcomings) in mind. You'll need to purchase additional split beads (RF chokes) to tame the common mode currents, and other maladies which will occur.

All remotely-controlled mobile antennas require some sort of motor to resonant the coil assembly. It is, by any definition, a DC powered, reversible, gear motor, but there ends the similarity. For example, early screwdriver antenna designs utilized a stripped down Black & Decker® rechargeable screwdriver assembly, hence the name screwdriver antenna. The truth is, the plastic-geared B&D® motor is barely up to the task, albeit some late-model designs still use it. This fact has lead most manufacturers to adapt a Pittman® gear-motor to handle the task. It is a wise choice, as Pittman® makes a series of rugged, and well-designed gear-motors to fit almost any application. Unfortunately, some cheaper models avoid the expense, and rely on questionable gear-motors. This fact brings up several esoteric design problems.

Some gear-motors are designed to operate only in one direction due to requisite torque demands. Thus, when they are operated in their unnatural direction, the torque is not only lessened, but their rotational speed is greatly reduced. Therefore, it is not uncommon for 80 through 10, versus 10 through 80 transition times to vary by a factor of 2 or more. While the problem may sound trivial, if you QSY a lot, it isn't!

Pittman® gear-motors, and all other makes for that matter, come in a variety of styles. Some compact models use planetary gear sets wherein the motor shaft is concentric with the output shaft. Other models (typically less expensive) use straight gears wherein the motor shaft is not concentric with the output shaft. Both work equally well in operating a screwdriver, but there is a penalty to be paid when using a non-concentric design—motor space!

At least two commercial screwdriver antenna models use an non-concentric design in their smallest models. By necessity, the resulting gear-motor is rather small is size—minuscule actually. While the current draw is low, the longevity of the gear-motor is suspect, especially when subject to stall conditions (end of travel). They are not, by any description, rugged! Unfortunately, the price you pay is no indication of what kind of gear-motor is being used, or its quality, or its ruggedness.

On the other end of the scale, are adapted motor designs. Several antenna manufacturers use gear-motor assemblies adapted from rechargeable hand drills. While rugged, their use is a screwdriver antenna is suspect from several angles, not the least of which is current draw. While a nominal Pittman® gear-motor may draw 200 mils on run, and perhaps 850 to 1,000 mils on stall, compare this to 2.5 amps run, and 8 amps on stall for the typical rechargeable screwdriver motor. This is higher current than most automatic antenna controllers can handle. In any case, power for any remotely tuned antenna should not be drawn from the transceiver's accessory port(s).

By the way, there are at least two antenna manufacturers who use a stepper motor design. This allows for precise repositioning of the resonant point, and decreases the length of time required to do so. However, the only controllers available to drive stepper motors are proprietary and rather expensive, often costing twice as much as the antenna itself!

There really isn't a standard-sized HF mobile antenna, so calling them that is a bit of a misnomer. On average, they're about 9 to 11 feet in overall length (including the whip), with some of them extending to 13 feet.

There really isn't a standard-sized HF mobile antenna, so calling them that is a bit of a misnomer. On average, they're about 9 to 11 feet in overall length (including the whip), with some of them extending to 13 feet.

All remotely tuned antennas, contain a gear-motor which turns a threaded rod (typically 1/4x20 all-thread) in and out of a nut or threaded boss attached to the bottom of the coil. This in turn moves the coil in and out of the mast. Contacts at the top of the mast slide on the outside of the coil, thus adjusting the resonant point.

Don Johnson, W6AAQ (sk), is credited by many as the father of the screwdriver antenna. His was, in fact, not the first motorized antenna, nor was it the first to hide the unused portion of the loading coil inside of a sleeve (mast). He certainly popularize it, and perhaps that's all that counts. Perhaps unfortunately, and contrary to popular belief, he never patented or copyrighted his design.

There are about 75 different manufacturers of screwdriver antennas. Some are copies, some improve on the basic idea, some are marketed better, some try to be something they're not, and some aren't worth the effort. Although there are exceptions, most on-line reviews need to be taken with a grain of salt, especially if they mention working lots of DX. Remember, a log sheet might be a measurement of bragging rights, but it sure isn't a comprehensive measurement of antenna efficiency or performance.

Quality wise, remotely controlled antennas run the gamut from poor to excellent, and as stated above, price isn't always an indicator. Some of the better brands are the Scorpion (at left), and Tarheel (right).

Most commercial antennas use beryllium copper as a contact material. It wears very well, and provides a secure connection when properly implemented. Some manufacturers would have you believe this is a dangerous practice. They cite the sloughing off of beryllium particles during normal operation. The facts are, the amount of beryllium sloughed off is almost nil, and so is the danger. Want to know the real reason they don't use beryllium finger stock? Cost!

Weather sealing is a requisite attribute. Some models are admittedly better than others, but sooner or later dirt and moisture take their toll. This fact exacerbates the wear on the finger stock that contacts the coil, and the other various rotating and sliding parts. If you operate on the lower bands (80 or 160 meters as the case may be), the coil is extended nearly its full length. This not only lessens the strength of the antenna, it exacerbates the weather sealing problem. This brings up an important caveat about screwdriver antennas.

Some of the cheaper models have very little coil support, especially on 80 meters when the coil is fully exposed. Hit a low hanging limb, and the antenna is toast! This condition is exacerbated on models with small diameter coils (<2 inches).

Scorpion is one of the newer screwdriver antenna manufacturers. Their machining, and build quality has to be seen to be believed! No other HF mobile antenna even comes close! Weather sealing is above average, and with 3 inch coils (#10, 6 tpi), efficiency is about as good as it gets. Several different models are available, so visit their web site for more details.

Their 680 model is shown upper left. It sells for ≈$800 to $900 depending on finish, and is worth every penny of it. If you order one, make sure you ask about lead times, as it is becoming a very popular choice. I've been using a Scorpion 680 since June 2009, and it has lived up to my expectations, and then some.

The Scorpion 680, has one of the highest average Qs of any commercially available, HF mobile antennas. It achieves this by using a liberal amount of Delrin® and Lexan®, and a minimal amount of metal, in close proximity to the coil. For those who think Q isn't important, you need to review the efficiency article.

Some models of remotely controlled HF mobile antennas, are available with 160 meter coverage. The inductance required to resonant a 160 meter, 8 foot long mobile antenna, is nearly 5 times greater than that required to resonant an 8 foot, 80 meter antenna. On average, this more than doubles the coil losses, which brings the input impedance very close to 50 ohms, and sometimes over it. This adds a level of complexity to proper input matching, and reduces efficiency to sub 1%, or even less if the coil diameter is less than 3 inches.

Some models of remotely controlled HF mobile antennas, are available with 160 meter coverage. The inductance required to resonant a 160 meter, 8 foot long mobile antenna, is nearly 5 times greater than that required to resonant an 8 foot, 80 meter antenna. On average, this more than doubles the coil losses, which brings the input impedance very close to 50 ohms, and sometimes over it. This adds a level of complexity to proper input matching, and reduces efficiency to sub 1%, or even less if the coil diameter is less than 3 inches.

If you own an 80 through 10 meter model, and you want to have 160 meter coverage, here's an alternative to buying a new antenna. Scorpion offers an add-on 160 meter coil for their 680 model which sells for $250. It should work with any screwdriver antenna, with a few caveats. First, as mentioned, matching can be a problem due to the higher input impedance on 160 meters vs. that of 80 meters, and above. So besides the coil, you'll need some easy solution to change the shunt matching coil. This can be done with plug-in coils like those sold by Scorpion, or by using a remote-controlled relay setup. The other issue is antenna strength. Cheaper models of the screwdriver are not sturdy enough to take the extra strain imposed by the coil. This extra strain is caused by the added length, weight, wind loading, and the leverage caused by the wind loading. Scorpion also offers a three loop cap hat, similar to the one shown above. It retails for $90.

The one item to keep in mind when buying any HF mobile antenna, is the warranty. Do yourself a favor, and read very carefully, even if it takes reading between lines. Oh! And don't forget to read the instructions. In most cases, they can be downloaded before purchase. Fact is, after reading some of them, you just might want to rethink your purchase!

All spirally-wound antennas are low in efficiency, as their coil Qs hover around 50 or less. A few of the 80 meter models have Qs less than 10! If you want a really lossy antenna, use one of the stubby 3 foot long versions! Their only attributes are, light weight, low wind loading (some models), and low cost (≈$30USD, less mount). This means they can be attached by just about any type of mount, some of which add to their overall losses (i.e.: license plate mount). Efficiencies range in the .3% to 20% (80 through 10 meters), and they typically don't need matching as the system losses bring the input impedance to near 50Ω.

All spirally-wound antennas are low in efficiency, as their coil Qs hover around 50 or less. A few of the 80 meter models have Qs less than 10! If you want a really lossy antenna, use one of the stubby 3 foot long versions! Their only attributes are, light weight, low wind loading (some models), and low cost (≈$30USD, less mount). This means they can be attached by just about any type of mount, some of which add to their overall losses (i.e.: license plate mount). Efficiencies range in the .3% to 20% (80 through 10 meters), and they typically don't need matching as the system losses bring the input impedance to near 50Ω.

Almost all spirally wound antenna masts are hollow which allows the whip to slide inside the mast far enough to affect the inductance of the loading coil. This fact makes them nearly impossible to tune (especially on 80 meters) without an antenna analyzer like the MFJ 259B. Secondly, even if you get a good match, the proximity of the tail of the whip to the coil further reduces their already poor Q factor. And most are made with an inferior grade of fiberglass which weathers badly. After just a few months use they get very stiff and brittle, and often snap off.

Spirally-wound antennas which do not have a lumped constant (loading) coil are very inefficient due to their excessive distributed capacitance. Thankfully, these are no longer being made.

Automatic Band-Switching Antennas

Swan, a reputable company, long out of business, once manufactured (what some might call) an automatic, band-switching antennas. As you can see in the photo, there were traps, tunable for each of the non WARC bands (80-10). These in turn shorted out (note the tap-clips on the main coil) a portion of the main loading coil. Both the traps and the taps were adjustable—a requirement due to differences in every installation.

Swan, a reputable company, long out of business, once manufactured (what some might call) an automatic, band-switching antennas. As you can see in the photo, there were traps, tunable for each of the non WARC bands (80-10). These in turn shorted out (note the tap-clips on the main coil) a portion of the main loading coil. Both the traps and the taps were adjustable—a requirement due to differences in every installation.

An earlier model called the 742, covered 20, 15, and 10, but was of a different design. Adjustable capacitors were in series with portions of the loading coil, in essence forming a series resonant trap. Sound in theory perhaps, but very poor in the real world as tuning was nearly impossible.

E. F. Johnson made a similar antenna (parallel resonant trap in this case) which covered 20 and 10 meters only. It too was difficult to tune, and tended to be very narrow banded. Both types were about as efficient as most monobanders of the era. Examples of these units are very rare, and are considered collectors' items.

The Hustler® (made by New-Tronics Antenna Corporation) is one of the oldest suppliers of mobile HF antennas in the world (the left photo depicts their standard RM-75 meter coil). You can even make them multi banded by using their "spider" mount (part number VP-1) to hold additional coils.

![]() Hustler® promotes their super coils as being the ultimate. They're not. In short, it is the large metal end caps on the super coil which makes them lossier than the standard ones. In other words, don't spend your money on the larger coils hoping for more efficiency. Besides the extra wind loading, their power handling capability isn't any better than the smaller ones, advertising hype notwithstanding.

Hustler® promotes their super coils as being the ultimate. They're not. In short, it is the large metal end caps on the super coil which makes them lossier than the standard ones. In other words, don't spend your money on the larger coils hoping for more efficiency. Besides the extra wind loading, their power handling capability isn't any better than the smaller ones, advertising hype notwithstanding.

Hustler® antennas have at least two additional drawbacks. One is moisture ingress. Water tends to get under the vinyl heat-shrink tubing covering the coil assemblies. This will detune the antenna and possibly cause arcing between the coil turns. This is the reason some authors suggest removing the vinyl sleeve which allows quicker drying. This is not a good idea as it allows road grime to build up on the coil windings which causes more problems than it solves.

If water ingress happens to you, here is a solution. Remove the whip assembly and place the coil in an oven at about 120° for 20 minutes or so. Don't leave them in too long, or use any higher temperature as you'll melt the heat-shrink. Once they cool down they'll be usable again. You can use a hair dryer for this operation, but be careful not to over heat the vinyl.

Recent manufactured models no longer have the compression type fitting to secure the whip; it has been replaced with a set screw. Whether this is a step backwards is perhaps moot, but the fact remains it is not as secure.

The another drawback is their masts. You often see examples of their fold over ones with a braided copper jumper across the hinge assembly to maintain a good connection. Unless you just have to use one, you're better off with their solid mast. In either case, you should use a base spring to minimize stress on the mast. If you notice any looseness (on this or any other mobile antenna), replace or tighten the part(s) before they come off while you're driving down the freeway!

Lastly, Hustler coils are secured to the mast by a pressed-in 3/8x24 stud with just five threads. The coil's 3/8x24 ferrule is also a press fit. It makes little difference if the coil unscrews, or the mast fails, or the ferrule fails, the coil will fly off! Over tightening them isn't the answer either, as this just hastens the connection's failure mode. If you use a cap hat, it behooves you to tether (guy) the antenna, as the extra wind load will hasten the loosening problem.

Whips, called stingers by the CB crowd, come is all lengths, and sizes. If there is an average, it is 72 inches (6 feet). A standard CB whip is 102 inches long (8.5 feet). At one time you could also purchase 108 inch, and 120 inch whips. Almost without exception, they're all made from bare 17-7 stainless steel wire, .200 inches in diameter, and topped with a brass tip which is too small to be called a corona ball. The wire is hammer straightened, and taper ground to .100 inches, starting at about 60 inches from the base.

Some smaller length whips (<48 inches), notably from Larsen, are copper plated, and covered with powder coated black paint. On the upper bands, the assumed advantages are more cosmetic, than real. On the lower bands (40 and below), a case can be made for using copper plated whips, but the field strength difference is minimal, perhaps one dB or so. The cost of copper plating a 17-7 stainless steel whip is about $50.

A standard CB whip, sans the mount, has a resonance point of about 27.5 MHz. If you use a standard ballmount, and spring (overall ≈110 inches), the resonant point will be very close to 25.5 MHz. As a result, you cannot use one on 10 meters without trimming its length. Further, it is not quite long enough for 12 meters (24.95 MHz). However, you can add a small shunt coil (≈.5 uH), which will lower the resonant point, and raise the input impedance on 12 meter just enough for most solid state transceivers.

Antenna weight can be a major purchasing factor. This is why most full-sized remotely controlled antennas end up being mounted on a trailer hitch type mount. As alluded to above, spending your hard-earned cash on a quality antenna, and then mounting it poorly, is counter productive. Remember, it is the mass directly under the antenna, not what's along side, that counts!

The most important point you need to establish is your personal level of satisfaction. The old proverb, one man's treasure is another man's trash, says it all. If your HF mobile setup is a treasure to you, then don't let someone tell you it isn't. If it is trash, then hopefully some of what you've read here will aid you in your quest for a better mobile station. Whatever you do, don't tell anyone you like it because you were able to work some rare DX. All that proves is your gullibility.